WHICH STYLE IMPACT CRUSHER DO YOU REQUIRE FOR YOUR APPLICATION ?

By integrating innovation into our core products, at Böhringer we pride ourselves in delivering superior value with premium quality and craftsmanship to our customers

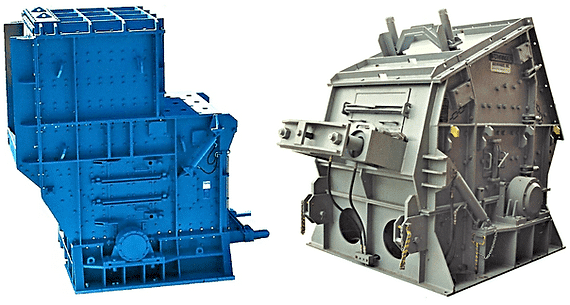

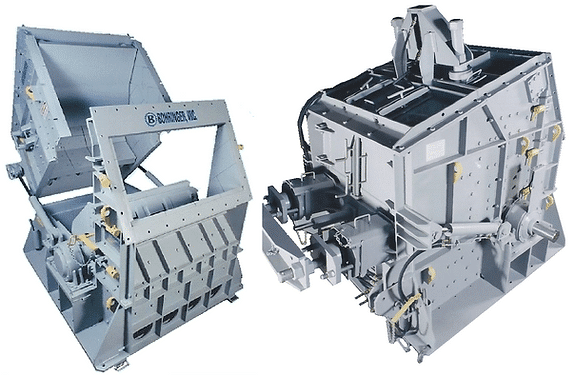

Primary Series Impactor “PB” AND “RC”

- High performance high capacity

- High reduction ratio

- Lower cost per ton operating cost

- Longer wear life due to proprietary specialized alloy castings

- Cubical crack free uniform particles

- Selective crushing

- Large expansion chamber

- Optimum rotor design

Primary – Secondary Series Impactor “RC”

- High performance high capacity

- High reduction ratio

- Lower cost per ton operating cost

- Longer wear life due to proprietary specialized alloy castings

- Cubical crack free uniform particles

- Selective crushing

- Large expansion chamber

- Optimum rotor design

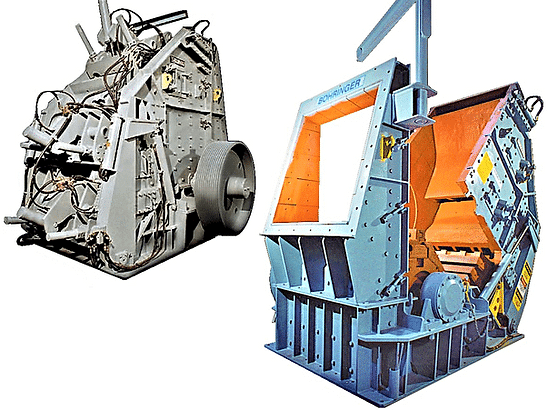

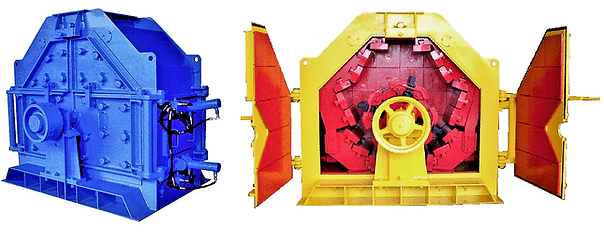

Secondary Series Impactor “HS”

- High performance high capacity

- High reduction ratio

- Lower cost per ton operating cost

- Longer wear life due to proprietary specialized alloy castings

- Cubical crack free uniform particles

- Selective crushing

- Large expansion chamber

- Optimum rotor design

Tertiary Series Reversible Impactor “HS-RV”

- High performance high capacity

- High reduction ratio

- Lower cost per ton operating cost

- Longer wear life due to proprietary specialized alloy castings

- Cubical crack free uniform particles

- Selective crushing

- Large expansion chamber

- Optimum rotor design

“A” leader in inertia crushing technology